In the concrete construction industry, reliable equipment delivery is just as important as equipment performance. From production to final shipment, every step plays a critical role in ensuring that concrete batching plants, mixers, and pumps arrive on site safely and ready for operation.

This article explains how professional concrete equipment manufacturers prepare machines for delivery, and why a well-managed shipment process matters for contractors worldwide.

1. Manufacturing with Delivery in Mind

Reliable delivery starts at the manufacturing stage. Equipment is not only designed for performance, but also for transportation efficiency.

Key considerations include:

- Modular structure for easy loading and installation

- Reinforced frames to withstand long-distance transportation

- Clearly labeled components for fast on-site assembly

By optimizing the design for transport, manufacturers reduce the risk of damage and shorten installation time at the jobsite.

2. Pre-Shipment Inspection and Final Checks

Before loading, each machine undergoes a comprehensive pre-shipment inspection.

Typical checks include:

- Structural integrity and welding quality

- Electrical systems and control panels

- Hydraulic pipelines and sealing performance

- Component completeness according to the packing list

Only after passing all inspections is the equipment approved for shipment.

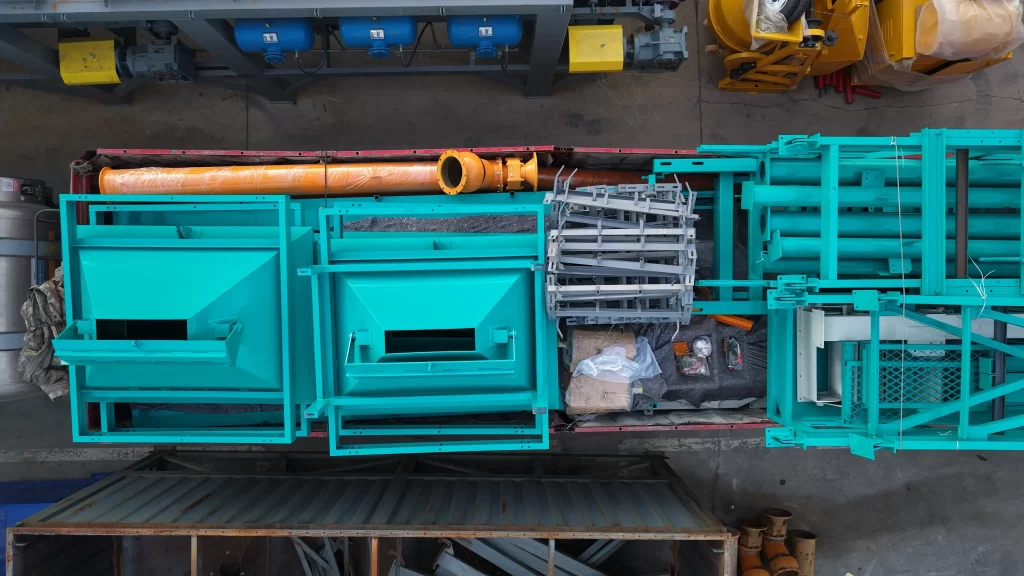

3. Professional Loading and Secure Packaging

Concrete equipment is heavy and often oversized, making proper loading essential.

Professional loading procedures usually involve:

- Crane lifting or forklift positioning under strict safety guidelines

- Anti-slip supports and reinforced fixing points

- Protective packaging for electrical parts and key components

This ensures the equipment remains stable during road, rail, or sea transportation.

4. Clear Documentation for Smooth Customs Clearance

Accurate documentation is critical for international deliveries.

Standard documents include:

- Commercial Invoice

- Packing List

- Bill of Lading

- Certificate of Origin (if required)

Clear and standardized documentation helps avoid delays at customs and ensures smooth delivery to the destination port.

5. Why Reliable Delivery Matters to Contractors

Delays or damaged equipment can significantly impact project schedules and costs.

Reliable delivery means:

- Faster installation and commissioning

- Reduced on-site troubleshooting

- Higher project efficiency and cost control

For contractors, choosing a manufacturer with a proven delivery process is a key factor in project success.

Conclusion

From factory production to final shipment, every step in the delivery process reflects a manufacturer’s professionalism and commitment to customers. Reliable concrete equipment delivery is not accidental—it is the result of careful planning, strict inspection, and experienced execution.

Manufacturers who focus on both product quality and delivery reliability provide real value to global construction projects.